|

Creating Customer Satisfaction for 37 Years! |

|

|

|

|

|||

|

|

|||

polycarbonate multiwall panel installation for greenhouses

|

|

|

|

|

|

|

|

|

| MULTIWALL | FASTENERS | TAPE | QUOTES | INSTALLATION ? | SHIPPING COSTS | RIDGE CAPS | POLY CHANNEL | ALUMINUM CHANNEL |

POLYCARBONATE MULTIWALL

ASSEMBLY & INSTALLATION GUIDE

'click here' for our prices

|

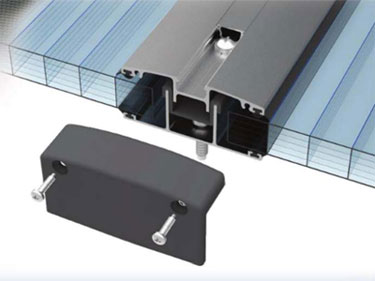

FASTENING For proper point fastening, 1" neoprene bonded washers should be used with screws. 48 inch wide sheets: Should be fastened to supports at all four corners , and at points 6" in from the edges of each purlin support. 72 inch wide sheets: Should be fastened to supports at all four corners, and at points 6" in from the edges of each purlin support and in the center of the purlin supports.

THERMAL EXPANSION Allow for thermal expansion during installation at a rate of 1/8" per 3 feet at 100 temperature differentials in both width and length of the sheet. Bronze panels will require an additional 30% space. IMPACT RESISTANCE Twinwall is one of the highest impact resistant materials available. From transport to installation, Twinwall will maintain its durability. Even when exposed to elevated temperatures over a long period of time, it will maintain its structural integrity. On-site, it will not crack or splinter, assuring you a high degree of safety.

INSTALLATION DIRECTION

The use of horizontal bars should

be avoided. Instead, order Twinwall in the proper length

Stiff fixing by means of adhesive or putty is to be avoided. Contact your distributor for recommended sealants. Exposed top and bottom ends of a sheet must always be sealed by means of the proper polycarbonate "U" profiles or an adhesive aluminum tape to prevent dust and dirt penetrating inside the ribs.

EXAMPLES

BENDING RADII Twinwall panels can be readily cold formed to many bending radii and can be fabricated on site to precise dimensions. It is important to avoid over tensing of the sheet, therefore, the minimum bending radius must be 150 times the thickness of the panel. Minimum Bending Radius = Ft./1

LOAD RESISTANCE This diagram is valid only when following conditions are followed:

|

Recommended Loading Guidelines

for Selecting Sheet Thickness and Purlin Spacing

(Sheet Supported on the Four Sides)

|

PLEASE NOTE: The charts below are meant only to show approximate loads that the polycarbonate multiwall can expect to sustain under the given circumstances. The charts do not reflect the capability of your buildings super structure (i.e. framing, footings and general design) to withstand loading. To insure that your building is able to withstand the expected loads in your area, contact your local building inspectors or designer. |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

WIND STAGNATION PRESSURE AT STANDARD HEIGHT OF 33 FEET (10 058 MM) |

|||||||

| Basic wind speed (mph)1 (x 1.61 for km/h) |

70 |

80 |

90 |

100 |

110 |

120 |

130 |

| Pressure (psf) (x 0.0479 for kN/m2) |

12.6 |

16.4 |

20.8 |

25.6 |

31.0 |

36.9 |

43.3 |

|

COMPARATIVE WEIGHTS (lb/ft) |

|||||

|

Thickness |

Twinwall |

Acrylic |

Glass Single |

PVC |

Glass Double |

|

6 |

0.266 |

1.45 |

3.02 |

1.72 |

6.15 |

|

8 |

0.350 |

1.93 |

4.10 |

2.29 |

8.19 |

|

10 |

0.410 |

2.92 |

5.12 |

2.87 |

10.24 |

|

16 |

0.555 |

3.87 |

8.20 |

- |

- |

| CLEANING Twinwall should be protected from abrasion by the installer. After installation, panels should be washed with mild soap or detergent and lukewarm water using only a clean sponge or soft cloth, then rinsed with clean water. Fresh paint, grease, and smeared glazing compounds maybe removed before drying by rubbing lightly wit a good grade of naptha or isopropyl alcohol followed by a final wash with mild soap or detergent and final rinse. |

![]()

![]()

![]()

![]()

| Copyright 2019, All Rights Reserved Including Page and Website "Look & Feel" |

Greenhouses Etcetera

"an EncepCo Company"

![]()

PO BOX 914

Benton City, WA 99320

toll free 1-888-966-7877