|

Creating Customer Satisfaction for 37 Years! |

|

|

|

|

|||

|

|

|||

| - greenhouses, greenhouse kits, shade cloth, homestead carts, greenhouse equipment & greenhouse glazing - | |||

polyethylene films are manufactured in widths of up to 50 feet

|

INSTALLATION |

'click here' to see the types of polyfilm available

'click here' for other types of greenhouse coverings you can buy

|

|

|

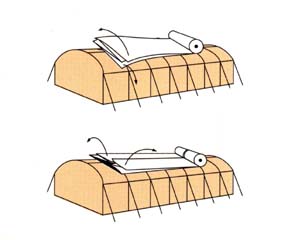

A. Instructions Polyethylene films are manufactured in widths of up to 50 feet to suit farmers' individual needs. They have convenient folds that make them easy to transport and install. The various folds are detailed on the back of each roll. 1. Do not open the polyethylene roll before installation. 2. Install the film as late as possible in the season (at plant time). 3. When installing triple-layer films, make certain that outside of the film is placed on top of the greenhouse, according to folds and installation instructions. 4. For proper placement of the film on the greenhouse it is important to keep the film intact and prevent decay. Suggested method: Place the polyethylene roll on top of the gable while tilting the roll toward the length of the greenhouse. All other methods where the roll is placed on the ground and the film is pulled towards the roof of the greenhouse (from front or side) are not recommended! 5. The film should be installed be installed during early morning hours (cold, without wind), and pulled evenly down the length. 6. Re-stretching is done after the film gets warmer. 7. Both surfaces of poly should be as smooth as possible to enable better water "sheeting". 8. Do not stretch film on hot days as it will contract when cool and may weaken. 9. Installation of the roof and sidewalls should be done at the same time. 10. Static air pressures between the two poly layers should be between 0.2 and 0.4 inches of water on a manometer. 11. Use outside air to inflate poly as it is less humid and less likely to contain chemicals. 12. Purlins with gutters will help remove condensation from film and reduce dripping. 13. Maintain a 3% slope for adequate water run-off. 14. Avoid direct spraying of any chemical on film surface. 15. Install a permanent manometer in each roof. Check manometer often to safeguard against developing tears or to discover a loose lock. Too little air on a windy day can cause excessive flapping and too much air on a hot day can cause stretching and weakening of the film. B. After Installation 1. With white acrylic paint stripes, cover all metal and wood parts that come in contact with the film (along the arches, ribs, supports, slats, etc.). 2. It is desirable to stretch polyethylene strips of 7.8" width between the arches (from gutter to gutter). Use only polyethylene strips. 3. Shade nets installed incorrectly that come in contact with the polyethylene film may harm the film. C. Ongoing Maintenance 1. Holes or tears must be repaired immediately with adhesive tape designed for polyethylene films. 2. When necessary, the films should be stretched, between seasons, and especially after strong winds. 3. In summer it is possible to whitewash the roof to reduce heat intensity. This should be done only with recommended materials for polyethylene films. It is not recommended to whitewash films immediately after laying them. Using adhesive materials makes cleaning the films more difficult. D. Use of Insecticides Sulphur and insecticides containing sulphur or halogens cause damage and erosion to polyethylene films. When using a spray gun, do not wet the film (especially when spraying tall or trailed crops).

ADDITIONAL INSTALLATION

INSTRUCTIONS

NOTE: For single sheet applications, there is an inside and outside to GT4-IR/AC 6 mm Film. You will be able to read the words GT4-IRIAC Film properly only when standing INSIDE the greenhouse. If you must read it in reverse, the film is upside down and the Drip-Control properties of this film will not work. For tube applications, both sheets will be the same and you do not have to worry about the correct direction. 1. Install two layers of sheeting or one roll of tubing to form an air space (bubble). This is recommended for areas where wind imposes repeated stress. Single layer installation may not have sufficient resistance to wind damage due to repeated flexing, and growers are cautioned that they use a single layer at their own risk. 2. Aluminum locking channels are recommended for securing the film to the structure. The locking channels often have plastic liners such as PVC and vinyl that contain organic compounds called plasticizers. Plasticizers can deteriorate the greenhouse film, so contact must be avoided by placing an extra layer of poly film between the actual GT4 & GT4-IR/AC Film and the plasticized material. This should inhibit any chemical reaction with the film. 3. To avoid heat build-up, all metal and wood surfaces that face the sun should be painted with a heavy coat of an industry approved white latex paint or white batten tape. Dark surfaces absorb solar heat and contact with such areas causes premature thermal degradation of the poly greenhouse covering. NEVER USE OIL BASED PAINT. The outside surface of the film, at areas where it comes into contact with the structure, should also be painted or protected with special white tape. It is not enough to paint the structure itself as this may accelerate UV is reflected and passes through the film twice. If wood is used, the Rutgers method of installations should be used. Treated wood often contains organic solvents that can deteriorate polyethylene film on contact. Paint these surfaces with white latex paint before attaching any poly film. 4. Polylocking devices with shading caps are recommended. Excessive deterioration of plastic film occurs at points where the film is tightly stretched across an unpainted metal surface and this surface is exposed to the sun. After installation, paint the polylocking device and film to a point, 6 inches above the locking device with undiluted greenhouse shading compound. 5. Film installed during warm temperatures will contract when the temperature cools down. Excessive stretching during contraction will reduce the film thickness making it weaker. 6. Maintain at least 3% slope for adequate run-off of water condensate. Purlins with gutters will help remove water condensate from the film and reduce drip. 7. Use outside air to inflate the bubble, as it is less humid and less likely to contain chemicals than inside air. Warm air from inside the greenhouse has a higher moisture level, and is a source of condensation when trapped in the bubble, which could reduce light transmission. 8. Proper air pressure in the bubble is extremely important. Manometer readings at 1/4 of water, indicates correct inflation. Too little air on a windy day can cause excessive flapping and too much air on a hot day can cause stretching and weakening of the film. 9. Use only repair tape recommended for use on polyethelyne greenhouse films. 10 Avoid direct spraying of any chemical, including herbicides, pesticides and fungicides on film surface, Avoid surface contact or extended exposure of the covering to bromine, chlorine, flourine, iodine, sulphur, petroleum and/or wood preservatives containing copper. The above instructions are recommendations only. |

|

|

'click

here' for detailed pdf polyfilm information booklet |

|

|

| LINKS TO OTHER COVERINGS | |

|

GREENHOUSE COVER POLYETHYLENE IN FLEXIBLE UV PANELING SHEETS |

|

POLY FILMS |

|

POLYCARBONATE RIGID TWINWALL SHEETING |

![]()

![]()

![]()

![]()

| Copyright 2019, All Rights Reserved Including Page and Website "Look & Feel" |

Greenhouses Etcetera

"an EncepCo Company"

![]()

PO BOX 914

Benton City, WA 99320

toll free 1-888-966-7877